What is the main difference between the wire arranging machine and the automatic wire arranging machine

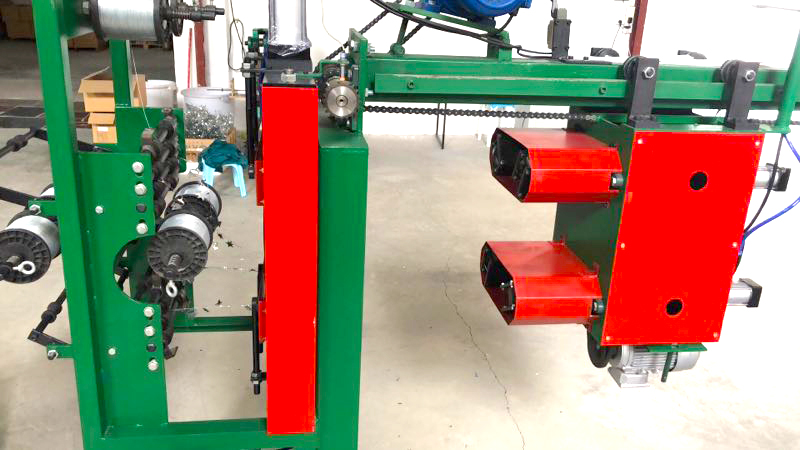

The automatic terminal machine can complete the functions of terminal trimming, stripping and crimping. It has functions similar to the computer stripping machine, and has stripping and crimping detection functions. There are wire arranging machines and automatic wire arranging machines on the market.

The mechanical type is driven by machinery and has a certain size to ensure stability and accuracy. But the price is favorable, about 60,000 (single head) -12W (double head).

The computer type uses slide rail movement and servo motor operation. Stability and accuracy are excellent, but the price is about 12W (single head) -23W (double head).

Generally, there are many reasons for bearing overheating in automatic terminal machines. The common reasons are as follows, let's take a look below.

The imbalance between the inner and outer rings of steel ball bearings is one of the causes of heat generation. The imbalance between the inner ring and outer ring of the terminal may be caused by machining. Since the base and end caps of the fully automatic terminal are processed separately, sometimes the bearing holes on the two end caps are not coaxial (that is, the center lines are not on the same line). In addition, poor assembly, uneven tightening of the screws on the end cover, and dust on the stopper may also make the inner ring and the outer ring unbalanced. If the inner and outer rings of the bearing are unbalanced, it will cause the steel balls and the inner and outer rings to scratch, thereby increasing friction and heating. If there is no other reason to check, please clean and reinstall the machine nozzle, and then tighten the screws diagonally one by one. Through the step-by-step automatic adjustment, a small amount of error in the processing process can be improved.

The belt is too tight or the axis of the automatic terminal and the driven machine are not on the same line, that is, they are not concentric, which will increase the bearing load and generate heat.

The daily maintenance method of the terminal manufacturer's fully automatic terminal: 1. (Stepping principle) The motor continuously rotates. There is an isolating switch inside the clutch, and each action is a standard "O", which is very common. 2. In the past five years, (silent) terminals with servers have appeared. It works differently from the above, but it just sends a message to the server, and then sends the message to the motor to perform the operation.

As long as the wire is worn out, you can put on the terminal mold, and after setting the parameters on the screen, you can produce it. Terminal machines can be divided into pneumatic terminal machines, terminal machines, ultra-quiet terminal machines, universal terminal machines, continuous terminal PI??N cutting machines, continuous wire stripping terminal machines, semi-automatic ultra-quiet terminal machines, wire stripping terminal machines, terminal machines, Wire stripping machine, small diamond terminal machine, series motor stator terminal machine, computer wire automatic wire stripping terminal machine, pin machine terminal machine, gold wire terminal machine, etc.

Shenzhen Tianheng Machinery Co., Ltd. is a Christmas craft gift machine, madder machine, rain silk machine, pine needle machine, automatic drawing machine, drawing machine, glue spreading machine, optical fiber peeling machine, color striping machine, wire arranging machine, rosin The company is headquartered in Longgang District, Shenzhen, and has a complete and scientific quality management system. It is a self-employed professional production and processing of products such as barrel crushers and slitting machine manufacturers. The integrity, strength and product quality of Shenzhen Tianheng Machinery Co., Ltd. have been recognized by the industry. Welcome friends from all walks of life to visit Shenzhen Tianheng Machinery Co., Ltd. for guidance and business negotiation.

tel